Sprockets may be classified into normal sprockets, HK sprockets together with other sprockets.

1. Normal sprocket

Regular sprockets are ANSI sprockets which may be engaged with conventional series roller chains. See P125 for dimensions.

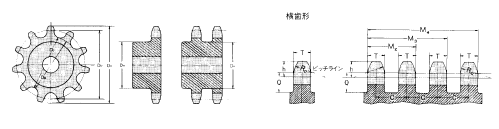

You will discover two varieties of tooth profiles: U-tooth and S-tooth.

2. HK sprocket

HK sprockets can be engaged with HK series roller chains, and these for single strand chains are identical to common sprockets. On the other hand, sprockets for several strand chains are different from regular sprockets in sprocket tooth profile.

3. Other sprockets

Other sprockets are developed according on the following calculation formulas to suit respective specialty chains.

The sprockets made use of for the following chains would be the similar since the regular sprockets in tooth gap form, but various in tooth thickness (sprocket tooth profile).

4. Calculation of sprocket dimensions

The dimensions of common sprockets and various standard sprockets are calculated as follows. In the beginning, the diameters of sprockets are  calculated from the following calculation formulas.

calculated from the following calculation formulas.

Next, sprocket tooth profile (the form of the tooth based on its thickness) is calculated in the following calculation formulas. (The values shown in the following pages were calculated by these formulas and thought to be the typical values.)

Calculation formulas for diameters and tooth gap types Calculation formulas for diameters

Calculation of pitch diameter, tip diameter and caliper diameter

The fundamental dimensions of the sprocket suitable to get a chain pitch of 1 mm are respectively identified as pitch diameter factor, tip diameter element and caliper diameter factor. The respective elements for respective numbers of teeth are listed below. If these variables are multiplied by chain pitch, the basic dimensions on the corresponding sprocket may be obtained.

Instance:

While in the situation of 80 (25.forty mm pitch) with 35 teeth Pitch diameter (Dp) = P×Pitch diameter factor

Calculation formulas for tooth gap types

Because the most rational tooth gap kinds through which the pressure angle changes in response on the elongation of the smoothly rotated roller chain using the lapse of services time, ANSI specify two sorts of tooth profiles: U-type and S-type. Usually, S-type tooth profiles are adopted in accordance with ANSI, and our typical sprockets also have S-tooth profiles.

Dimensions of Sprocket

Tags