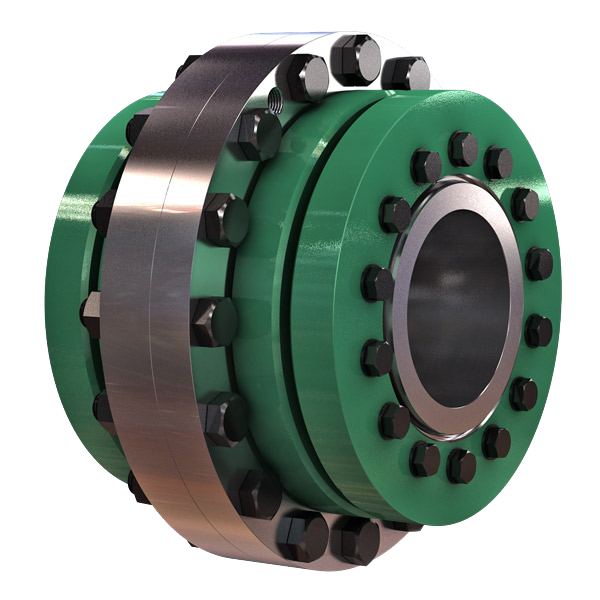

Product Description

Ductile Cast Iron En545 Fitting Connector Universal Wide Range Flange Coupling

Description :

| Material | Ductile iron grade 500-7/ 450-10 in accordance with ISO 1083 |

| Standard | EN545, EN598, ISO2531, BS4772, AWWA C110, AWWA C153, GB/T13295 |

| Certificate | ISO9001, ISO14001, SGS,WRAS |

| Test | In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test |

| Connection | DIN2576, BS4504 PN16, ANSI B16.5 |

| Flange Drilling | PN10 / PN16 / PN25 according to BS4504 |

| Internal Lining | Cement, conform to ISO4179/ Fishon Bonded Epoxy (FBE) |

| External coating | Zinc + BiHangZhou, conform to ISO8179/ Fishon Bonded Epoxy (FBE)/ Epoxy/ BiHangZhou |

| Usage | Jointed by the bolts, nuts and sealed by the gaskets |

| Note | the gaskets, bolts & nuts are supplied respectively as your special requirement |

——RELATED PRODUCTS——

ZheJiang CHINAMFG COMMERCIAL CO.,LTD (hereinafter referred to as the “DEKO group”), the company is located in China’s “Land of Casting” -ZheJiang province, we are engaged in the wholesale, retail, research and development and sales of products for the integration of import and export company and we assembled fist-class factories in domestic, using the most advanced production facilities and technology to provide the best quality for our customers, DEKO group‘s products has been covered in the municipal engineering projects, drainage system, constructions, fire control system and urban public facilities related products, such as Cast Pipe,Pipe Fitting,Valve, Manhole cover, Hardware products, Aluminum die casting, Aluminium profile, Public Illumination,Urban Furnishing,Flange and Pipe Repair Clamps etc., CHINAMFG group has been undertaking some domestic and foreign projects every year round and has always been praised by our customers. At present our products have been exported to Europe, South America,Africa, Asia, Middle East and Southeast Asia etc.

DEKO group adhering to the”first-class brand,first-class service”purpose, to keep improving product quality as the basis and advancing with the times, providing high quality, high standard products to our customers, CHINAMFG group will develop into a”first-class products,first-class quality,first-class service”global company in future.

Q. Do you accept OEM service?

A: Yes, we do.

Q. Can I get free samples?

A: Yes, And you only need to bear the delivery costs, if the samples are not too big.

Q.What information should I let you know if I want to get a quotation?

A: Size, design standard, material, package, Quantities, etc…

Q.How can you assure your quality?

A:We have equipped the modern quality control system as well as our quality engineer always check step by step from mold ,production before shipment.

How Does a Flange Coupling Handle Angular, Parallel, and Axial Misalignment?

A flange coupling is designed to accommodate various types of misalignment that may occur between two shafts. Here’s how it handles different types of misalignment:

- Angular Misalignment: Flange couplings can handle angular misalignment by allowing a slight flexing or bending of the flexible elements. The coupling’s flexible components, such as elastomeric or metallic elements, can bend and compensate for angular misalignment between the shafts. This flexibility ensures that the coupling can transmit torque smoothly even when the shafts are not perfectly aligned in a straight line.

- Parallel Misalignment: Flange couplings can also accommodate parallel misalignment between the shafts. When the two shafts are slightly offset in a parallel direction, the flexible elements in the coupling can move laterally to accommodate this misalignment. This lateral movement helps prevent excessive forces and wear on the coupling and connected equipment, ensuring efficient power transmission even in slightly misaligned conditions.

- Axial Misalignment: Axial misalignment refers to the situation when two shafts are displaced along their common axis. Flange couplings are not specifically designed to handle large axial misalignment. However, certain types of flange couplings may have limited axial movement capabilities due to the flexibility of their components. In some cases, an additional feature like an end float or sliding flange design may be incorporated to accommodate limited axial movement.

It is important to note that while flange couplings can handle a certain degree of misalignment, excessive misalignment can lead to premature wear and failure of the coupling. Regular maintenance and proper alignment of the shafts are essential to ensure the coupling’s optimal performance and longevity.

Can Flange Couplings Be Used in Food Processing and Pharmaceutical Industries?

Yes, flange couplings can be used in food processing and pharmaceutical industries, provided they meet certain requirements and standards to ensure hygiene and product safety. These industries have stringent regulations and guidelines to prevent contamination and maintain the quality and purity of their products. When selecting flange couplings for such applications, several considerations must be taken into account:

- Material Selection: The flange coupling material must be food-grade or pharmaceutical-grade and comply with industry-specific regulations. Stainless steel, particularly austenitic grades like 316L, is commonly used due to its excellent corrosion resistance and ease of cleaning.

- Hygienic Design: Flange couplings for these industries should have a hygienic design that minimizes crevices, dead spaces, and surface roughness where bacteria or contaminants could accumulate. Smooth surfaces and seamless construction help facilitate thorough cleaning and sterilization.

- Sealing and Lubrication: Proper sealing is essential to prevent any potential leaks or ingress of contaminants. Food-grade or pharmaceutical-grade lubricants should be used to ensure that there is no risk of contamination from the coupling’s lubrication.

- Certifications and Compliance: Flange couplings intended for use in food processing and pharmaceutical industries should have relevant certifications, such as FDA (U.S. Food and Drug Administration) approval, EU regulations (e.g., EC No. 1935/2004), and compliance with industry standards like 3-A Sanitary Standards.

- Cleanability: Flange couplings should be designed for easy disassembly and cleaning to maintain the required hygiene standards. This may involve quick-release or tool-less designs that allow for frequent inspection and cleaning without impeding production processes.

- Resistant to Corrosive Cleaning Agents: In food processing and pharmaceutical industries, aggressive cleaning agents may be used. The flange coupling material should be resistant to these substances to avoid degradation and maintain the coupling’s integrity over time.

By meeting these criteria, flange couplings can be safely used in food processing and pharmaceutical applications without compromising product quality or safety. It is crucial to work with reputable manufacturers or suppliers who understand the specific requirements of these industries and can provide couplings that adhere to the necessary standards.

Can Flange Couplings Handle Misalignment Between Shafts?

Flange couplings are designed to handle a limited amount of misalignment between shafts. However, their ability to accommodate misalignment is more limited compared to flexible couplings.

The misalignment that flange couplings can tolerate is typically in the form of angular misalignment and axial misalignment. Angular misalignment occurs when the axes of the two shafts are not perfectly aligned, causing the flanges to be at an angle to each other. Axial misalignment, on the other hand, refers to the displacement of one shaft along its axis with respect to the other shaft.

It is essential to note that excessive misalignment can lead to increased stress on the coupling and connected equipment. Flange couplings may not be suitable for applications with significant misalignment requirements.

For applications that involve substantial misalignment or require flexibility to accommodate misalignment, flexible couplings are more appropriate. Flexible couplings, such as elastomeric or jaw couplings, can handle both angular and axial misalignment more effectively than rigid flange couplings.

In summary, while flange couplings can handle some degree of misalignment, their primary strength lies in their ability to transmit high torques and withstand heavy loads in more rigidly aligned shaft arrangements. When dealing with misalignment-sensitive systems, it is best to consider flexible coupling options to ensure optimal performance and prevent premature wear on the equipment.

editor by CX 2023-10-02