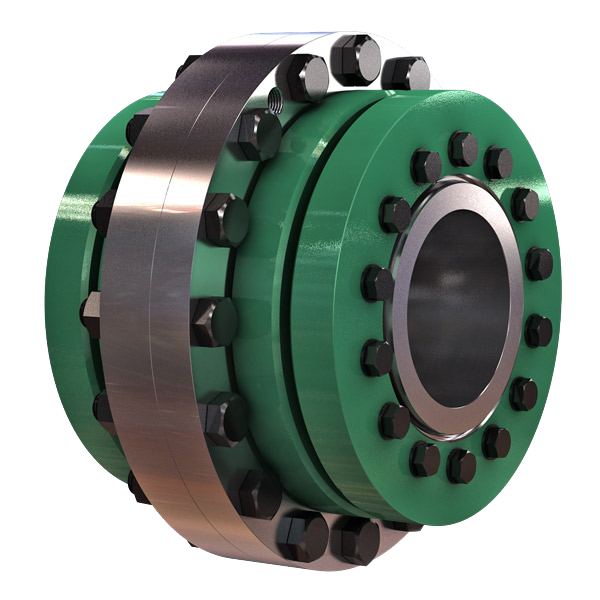

Product Description

| Product Name | hrc coupling |

| Material | cast iron |

| Type | HRC 70, HRC 90, HRC 110, HRC 130, HRC 150, HRC 180, HRC 230, HRC 280. |

| Structure | 2 shaft ( 1 / 1a / 1b )+ spider |

| Bore size | 0~40mm |

| Weight | About 3.3-10 kg / pcs |

| packing | plastic bag +paper box +wooden box +wooden pallet |

1. Engineering: machine tools, foundry equipments, conveyors, compressors, painting systems, etc.

2. Pharmaceuticals& Food Processing: pulp mill blowers, conveyor in warehouse, agitators, grain, boiler, bakery machine, labeling machine, robots, etc.

3. Agriculture Industries: cultivator, rice winnower tractor, harvester, rice planter, farm equipment, etc.

4. Texitile Mills: looms, spinning, wrappers, high-speed auto looms, processing machine, twister, carding machine, ruler calendar machine, high speed winder, etc.

5. Printing Machinery: newspaper press, rotary machine, screen printer machine, linotype machine offset printer, etc.

6. Paper Industries: chipper roll grinder, cut off saw, edgers, flotation cell and chips saws, etc.

7. Building Construction Machinery: buffers, elevator floor polisher mixing machine, vibrator, hoists, crusher, etc.

8. Office Equipments: typewriter, plotters, camera, money drive, money sorting machine, data storage equipment, etc.

9. Glass and Plastic Industries: conveyor, carton sealers, grinders, creeper paper manufacturing machine, lintec backing, etc.

10. Home Appliances: vacuum cleaner, laundry machine, icecream machine, sewing machine, kitchen equipments, etc.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Factors to Consider When Choosing a Flange Coupling for a Specific System

When selecting a flange coupling for a specific system, several factors need to be taken into consideration to ensure optimal performance and reliability. Here are the key factors to consider:

- 1. Load and Torque Requirements: Determine the maximum load and torque that the flange coupling will experience in the application. This includes both static and dynamic loads. Select a flange coupling that can handle these loads without exceeding its rated capacity.

- 2. Shaft Diameter: Measure the diameter of the shafts that will be connected by the flange coupling. Ensure that the coupling’s bore size matches the shaft diameter to provide a proper fit and secure connection.

- 3. Misalignment Tolerance: Consider the amount of misalignment that the system may experience during operation. Flange couplings are available in different designs, and some can accommodate higher levels of misalignment than others. Choose a coupling that can handle the expected misalignment to prevent premature wear and stress on the system.

- 4. Operating Speed: Determine the rotational speed of the connected equipment. High-speed applications may require precision balancing and careful selection of materials to prevent issues like resonance and excessive vibration.

- 5. Environmental Conditions: Consider the environmental factors the flange coupling will be exposed to, such as temperature, humidity, dust, and chemicals. Choose a material and coating that can withstand the specific environmental conditions to prevent corrosion and degradation.

- 6. Space Limitations: Evaluate the available space for installing the flange coupling. Some applications may have limited space for coupling installation, requiring compact designs or custom solutions.

- 7. Serviceability: Assess the ease of installation and maintenance of the flange coupling. A coupling that is easy to install and service can reduce downtime and maintenance costs.

- 8. Compatibility: Ensure that the flange coupling is compatible with the equipment and shafts in the system. Consider factors such as keyways, set screws, and other connection methods.

- 9. Material Selection: Choose the appropriate material for the flange coupling based on factors like load, temperature, and corrosion resistance. Common materials include steel, stainless steel, aluminum, and various alloys.

- 10. Cost: Compare the cost of different flange coupling options, considering both the initial investment and long-term maintenance expenses. Balance the cost with the desired performance and reliability.

It is essential to consult with coupling manufacturers or industry experts to ensure the flange coupling’s suitability for the specific application. Properly selecting and installing the right flange coupling can contribute to the efficiency, reliability, and longevity of the connected machinery and system.

How Does a Flange Coupling Help in Power Transmission Efficiency?

A flange coupling plays a crucial role in improving power transmission efficiency in mechanical systems. It efficiently transfers power from one shaft to another while maintaining the alignment and minimizing energy losses. Here’s how flange couplings contribute to power transmission efficiency:

1. Direct Power Transfer: Flange couplings provide a direct connection between the driving and driven shafts, ensuring a solid and reliable power transfer without the need for intermediate components. This direct coupling minimizes power losses that can occur in systems with multiple components and connections.

2. Rigid and Precise Connection: Rigid flange couplings offer a precise and firm connection between shafts, minimizing angular and parallel misalignments. By reducing misalignment, energy losses due to friction and vibrations are minimized, leading to more efficient power transmission.

3. Absence of Slippage: Flange couplings are designed to provide a secure and non-slip connection between shafts. Unlike some other coupling types that might experience slippage under heavy loads or during acceleration, flange couplings maintain constant power transmission without loss of torque.

4. High Load-Carrying Capacity: Flange couplings are capable of handling high torque and axial loads, making them suitable for heavy-duty applications. The ability to handle these loads without deformation ensures efficient power transmission even in demanding industrial settings.

5. Minimal Maintenance: Flange couplings are generally low-maintenance components. Once properly installed, they require minimal attention, reducing downtime and enhancing overall system efficiency.

6. Balancing and Vibration Damping: Some flange coupling designs, such as flexible and torsionally flexible couplings, provide additional benefits like vibration damping and torsional flexibility. These features help to absorb shocks and vibrations, ensuring a smoother power transmission and protecting connected equipment from damage.

7. Selection of Appropriate Flange Type: Choosing the right type of flange coupling for a specific application is crucial for optimal power transmission efficiency. Different flange designs offer varying levels of flexibility and alignment capabilities, allowing engineers to select the most suitable coupling based on the system requirements.

In summary, flange couplings facilitate efficient power transmission by maintaining alignment, reducing energy losses, and providing a robust and reliable connection between shafts. Properly selected and installed flange couplings help improve the overall efficiency and performance of mechanical systems.

How Do Flange Couplings Compare to Other Types of Couplings in Terms of Performance?

Flange couplings offer several advantages and disadvantages compared to other types of couplings, and their performance depends on the specific requirements of the application. Here’s a comparison of flange couplings with other common coupling types:

1. Flexible Couplings:– Misalignment Handling: Flexible couplings, such as elastomeric or jaw couplings, excel in handling shaft misalignment, both angular and axial. Flange couplings have limited misalignment accommodation compared to flexible couplings.- Vibration Damping: Flexible couplings can absorb and dampen vibrations, reducing the impact on connected equipment. Flange couplings, being rigid, provide less vibration dampening.- Load Capacity: Flange couplings can handle higher torque and loads due to their rigid design, making them suitable for heavy-duty applications. Flexible couplings have a lower torque and load capacity but offer other benefits.2. Gear Couplings:– Misalignment Handling: Gear couplings are capable of handling higher levels of misalignment, especially angular misalignment.- Load Capacity: Gear couplings are robust and can transmit high torque and handle heavy loads similar to flange couplings.- Complexity: Gear couplings have a more intricate design compared to flange couplings, which may result in higher manufacturing costs.3. Disc Couplings:– Misalignment Handling: Disc couplings can accommodate moderate misalignment, but they are not as effective as flexible couplings in this aspect.- Torsional Stiffness: Disc couplings offer high torsional stiffness, making them suitable for precise motion control applications.- Temperature Resistance: Disc couplings can withstand higher operating temperatures compared to some other coupling types.4. Fluid Couplings:– Slip Capability: Fluid couplings provide slip between input and output, allowing for smoother starts and reduced shock loads during acceleration.- Efficiency: Fluid couplings may introduce power losses due to fluid shear, resulting in lower efficiency compared to some other coupling types.In summary, flange couplings are ideal for applications requiring high torque transmission and rigid shaft connections. They are commonly used in industrial machinery, pumps, and compressors. However, for applications with misalignment issues, vibration concerns, or the need for torsional flexibility, other coupling types like flexible couplings or gear couplings might be more suitable. The choice of coupling depends on factors such as the specific application, misalignment, load requirements, and the desired level of vibration isolation or damping needed in the system.

editor by CX 2024-03-05