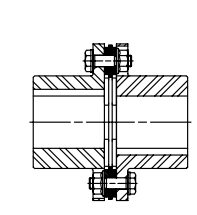

Industrial SU Type

The SU Kind coupling features a single flex plane with two hubs in addition to a single disc pack. It’s suitable for angular and axial misalignment only. Two SU couplings tend to be mixed by using a shaft

to produce a floating shaft coupling. The shaft is usually hollow for long light weight floating shaft couplings.

Industrial SX Form

This can be the normal coupling style that contains two hubs, a stock length spacer made to meet marketplace typical lengths, and two unitized disc packs. The coupling has two flex planes, 1 at every single disc pack, allowing this coupling to accommodate parallel, angular, and axial misalignment with specified limits. The coupling is available in six and eight bolt designs and bore sizes as much as 13 inches (330mm) over the biggest size. Custom spacer lengths is usually manufactured to meet specific shaft separations necessary for precise applications. The SX coupling might be fitted with overload bushings to safeguard the disc packs in above torque disorders and will act as an anti-flail gadget. SX couplings are assembled at the time of installation to the products wherever the coupling will be in services.

Industrial DI Sort

The DI Style coupling has a “Drop-In” spacer assembly that is certainly assembled with the factory. The coupling consists of two hubs along with a spacer assembly comprising of the spacer, two unitized disc packs, and two guard rings. The disc packs are bolted on the spacer and guard rings on the factory employing the torque values advisable by Lovejoy to the disc pack bolts. Using the hubs mounted about the shafts, the complete disc pack assembly is usually “Dropped In” spot among the 2 hubs. The hubs are piloted to be sure suitable centering in the spacer assembly. This piloting serves as an anti-flail attribute and aids while in the coupling’s ability to meet the balance specifications mandated by API. This design coupling is built to meet the stability and anti-flail demands specified in API-610.

Oversized, or Jumbo, hubs can be found for use with the DI Form coupling to permit for bigger bore sizes on most DI coupling sizes. This enables for that use of smaller DI couplings in applications wherever a smaller dimension coupling can nonetheless accommodate the application torque.

Industrial SXC Form

The SXC Style could be the near coupled variation on the SX Style coupling. The SXC is just like the SX coupling in that the disc packs are connected when the coupling is installed. Within the near coupled units, the hubs are turned inward and therefore are mounted within the spacer. Note that with the hubs inside the spacer, the maximum bore permitted inside the hub will be decreased. The SXC couplings could be made use of with one or each hubs turned outward to permit the coupling to accommodate distinct shaft separations.

Industrial SXCS and SXCST Types

The SXCS and SXCST Styles have split spacers as well as disc packs is usually serviced or removed devoid of moving the hubs about the shafts and devoid of moving the gear. The SXCS Form has the bolts that connect the hubs for the split spacer put in through the ends of your  couplings. The SXCST possess the bolts installed from within the spacer pointing outward in the direction of the hubs.

couplings. The SXCST possess the bolts installed from within the spacer pointing outward in the direction of the hubs.

Additional Types

Disc Coupling Overview

Tags